|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PA UT (PAUT): ISONIC EXPERT DUET Technology

ISONIC DUET and ISONIC DUET M software applications were created for the inspection of various welds, namely:

- planar butt welds

- circumferential butt welds (girth welds)

- longitudinal welds (long seams)

|

ISONIC DUET and ISONIC DUET M software options are available for the ISONIC 3510T / ISONIC 3510, ISONIC 2010, and ISONIC 2009 UPA Scope instruments

The sectorial and / or linear cross-sectional scan files composing the scan plan for implementing of the ISONIC DUET Technology based inspection should be created in the one side inspection software either ISONIC EXPERT, ISONIC EXPERT A, or ISONIC EXPERT CU corresponding to the shape of the weld to be examined

True to geometry coverage and imaging of the weld & HAZ volume is provided for each PA probe separately and in the overlap; each PA probe may implement a number of insonification schemes simultaneously (2 X MULTIGROUP mode)

For the first time ever the complimentary TOFD inspection with forming of up to 4 separate shots (depending on the material thickness) may be performed out of the same pair of PA probes. This novel way of implementing TOFD examination has been proven by the numerous comparison tests with regular probes connected to various types of conventional instruments (channels) and it is already recognized by the international standard EN ISO 13588:2012 and a number of other national and industry codes

The video below illustrates TOFD A-Scan obtained out of a pair of PA probe for the sharp edged planar vertical and compact discontinuities:

The dual modality (PA + TOFD) inspection with use the same pair of PA Probes extremely simplifies and lightens the structure of the scanning frame

Whilst scanning the weld from both sides along the fusion line the instrument performs:

- 100% raw data capturing

- True-to-geometry cross-sectional imaging for each probe separately and in the overlap

- Generating of the corresponding strip chart representing top view of the weld and HAZ

2 videos below show the simplicity of quick organizing of DUET Scan Plan for:

- Performing PAUT and TOFD coverage of the weld out of the same pair of PA Probes

- Performing PAUT and TOFD coverage of the weld out of the pair of PA Probes and regular TOFD probes

Typical ISONIC DUET live indications for PA and TOFD coverage of planar butt weld out of just a pair of PA probes are presented in the video below

Maximal setup compactness and the top level performance of the ISONIC series PA instruments allows utilizing of the ISONIC DUET inspection even without the scanner through use of the simplest embodiment without reducing the inspection reliability and quality of the data recording and presentation

As every PA instrument of ISONIC series is fully controllable by the PC through Ethernet the same ISONIC DUET software that runs in the instrument may be installed in the external PC if it is necessary and possible to utilize the large screen data presentation

The videos below illustrate the inspection process, explain the screen observations and some unique postprocessing features of the ISONIC EXPERT DUET / DUET M technology:

The movies below illustrate DUET inspection process when the instrument is controlled by / the data is captured and imaged in the external PC:

In addition ISONIC DUET M software allows using of 1 or 2 additional pairs of regular TOFD probes connected to the conventional channels

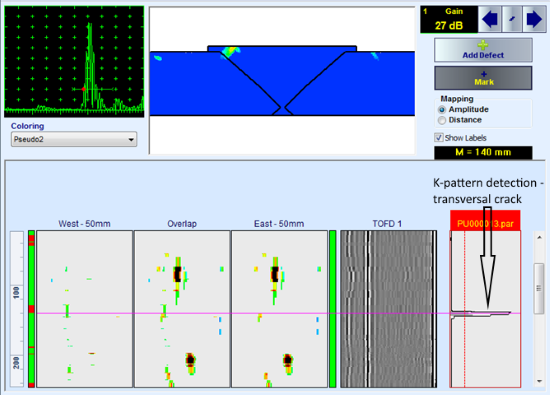

It is also provided the ability of simultaneous K-Pattern pitch-catch detection of the transversal cracks with use of conventional shear wave probes

The movie below illustrates the automatic scanning solution for the implementing of ISONIC DUET inspection of 40 mm thickness circumferential weld

The movie below illustrates performing of the comparison of the ISONIC DUET inspection results with radiography

There is a number of manual scanners available for implementing of scanning with a pair of PA probes, such as, for example:

- SSBC 288700 - Advanced Scanner for Weld Inspection

- SSBC 288850 - Modular bracelet scanner for the inspection of butt welds in the small diameter pipes

- SSBC 288690 FR - Simple TOFD / EXPERT DUET Scanner Frame for carrying one pair of probes

- etc

Note: In order to accelerate the data stream the videos above are linked to the Youtube. In case the YouTube may not be accessed from your location please use the link below

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DOWNLOAD AND PLAYBACK THE EXEMPLARY INSTRUMENTS FILES

|